RMA

RMA Management in EMS Factories

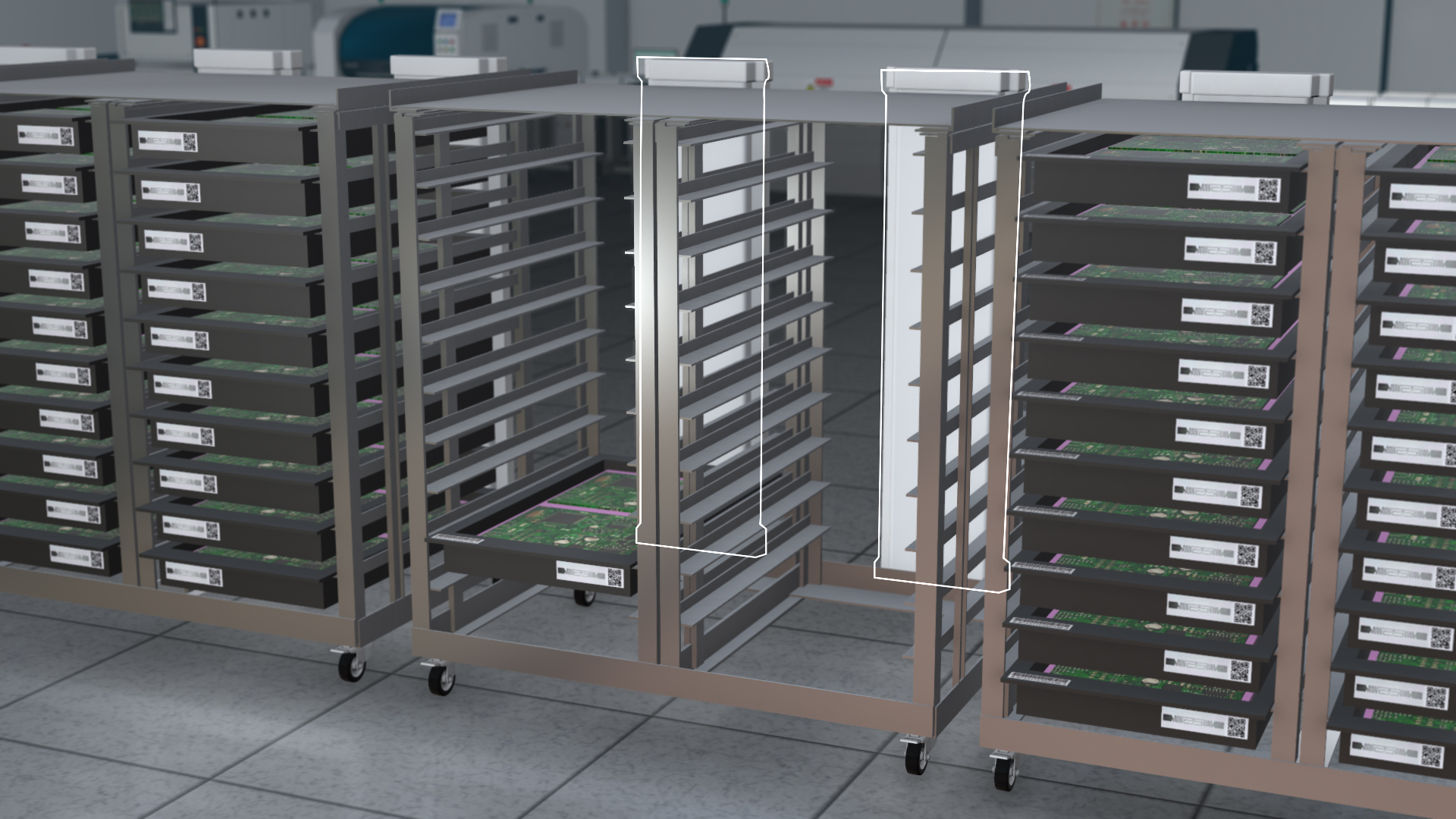

To improve PCBa yields, daily failure analysis of defective products is required. However, due to the large number of defective products, it is difficult to clearly track their storage locations. If operators fail to hand over the records, the search process can become time consuming and labor intensive, sometimes taking an entire day just to locate the defective products, causing significant inconvenience for customers.

Success Stories

By binding the serial numbers of defective products with the RFID tags on their carriers, and using RFID antennas mounted on the carts to detect these tags, the system can track which cart the defective products are placed on, improving search efficiency.

Benefits

After implementing the smart tracking system, the time required to locate defective products can be reduced from one day to just 10–15 minutes. This accelerates failure analysis and repair efficiency, enabling faster shipments and increasing production line capacity.