Logistics

Turnover Boxes Tracking for Automotive Parts Suppliers

A US auto parts manufacturer faced turnover box losses after shipments to customers, with each box worth about USD 125, resulting in high costs. Manual counting of turnover boxes during returns is time-consuming and prone to errors, increasing management difficulty and losses.

Success Stories

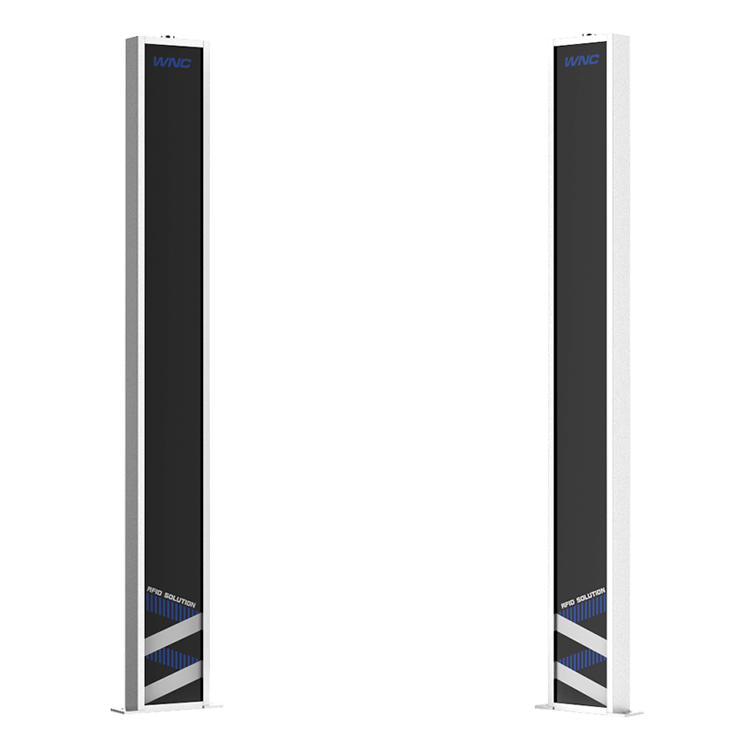

Implementing the WNC RFID Portal not only saves labor and time for inventory counting and greatly improves accuracy, but also tracks the flow of turnover boxes, helping trace and remind customers to return them.

Benefits

Implementing the system greatly improves inventory efficiency and accuracy, while tracking turnover box movements. This significantly reduces losses, supports reuse for environmental benefits, saves substantial box purchase costs, and achieves ROI within six months. (As reported in the Wall Street Journal.)

Logistics Cage Cart Management

A situation that happens often during shipping is that cage carts carrying items are lost or moved to the wrong place, resulting in missing items or items delivered to incorrect locations, which leads to delays and late delivery penalties.

Success Stories

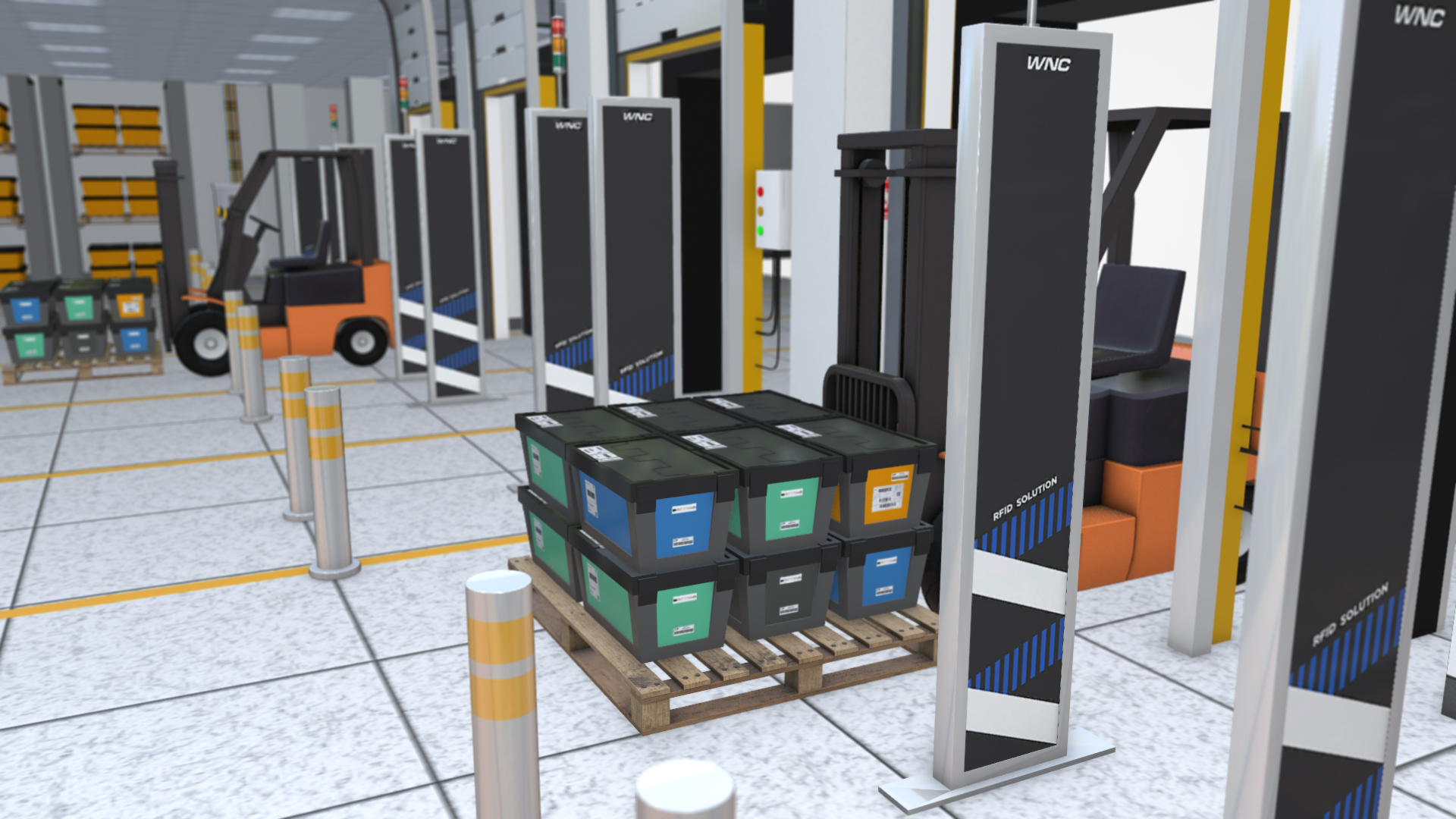

WNC's RFID Portal can quickly and accurately track cage carts and the items on each cart, reducing item search time and delivery errors as well as boosting shipping efficiency.

Benefits

Real-time monitoring of cage cart quantity and locations in real time to prevent shipment delays due to cart shortages. Accurate tracking of when carts enter/exit warehouses to ensure first-in, first-out approach is being followed. Arranging of deliveries based on urgency to avoid late delivery penalties and to boost warehouse logistics efficiency.

Cold Chain Management in Food Processing Factories

In food processing factories, the temperature at each station as well as the duration that food items stay at each station must be strictly controlled. Without real-time location and temperature monitoring, it is difficult to detect issues in the cold chain, resulting in insufficient supply chain transparency, poor item traceability, and increased food safety risk.

Success Stories

By deploying WNC’s RFID Portal at temperature-controlled checkpoints and utilizing UHF RFID handheld readers and temperature sensors, the location and temperature data of food items can be quickly uploaded to management platforms, enabling fully automated item tracking, real-time cold chain monitoring, and robust item traceability.

Benefits

With real-time tracking and monitoring, location and temperature data are automatically captured and uploaded at every stage, from production to storage and transportation, reducing the amount of manual work needed. The system can also instantly detect any temperature issues in the cold chain and send out an alert, ensuring food quality and safety. All data is integrated into a single platform, enhancing supply chain transparency and item traceability, and in turn reducing the time needed to resolve issues.

Apparel Industry Logistics Warehouse

When large volumes of goods from apparel factories are moved in and out of warehouses, conducting item receiving manually is time consuming and makes it difficult to quickly verify deliveries against purchase orders, in turn making logistics and warehouse management more challenging.

Success Stories

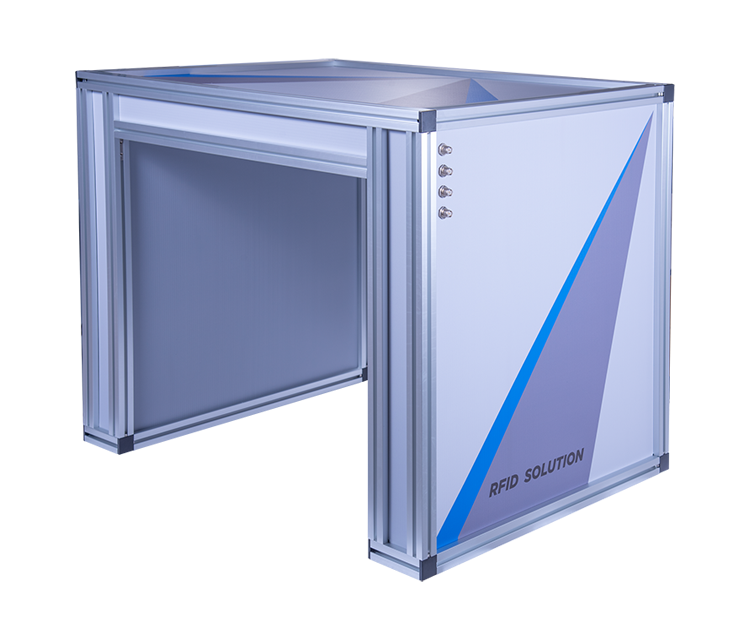

WNC's RFID Tunnel, coupled with a conveyor system, is able to automatically scan and read all RFID tags in product containers as they enter/exit warehouses. In tests involving 800 to 1,200 boxes of goods, the RFID Tunnel was able to simultaneously read tags in the boxes and compare their content against shipping lists, achieving 100% accuracy.

Benefits

The RFID Tunnel greatly improves item receiving efficiency at warehouses and ensures that the items delivered match the quantities listed on orders. It also provides clear item traceability and reduces the amount of time spend on communicating and resolving discrepancies between deliveries and purchase orders.

Bedding and Clothing In-and-out Management

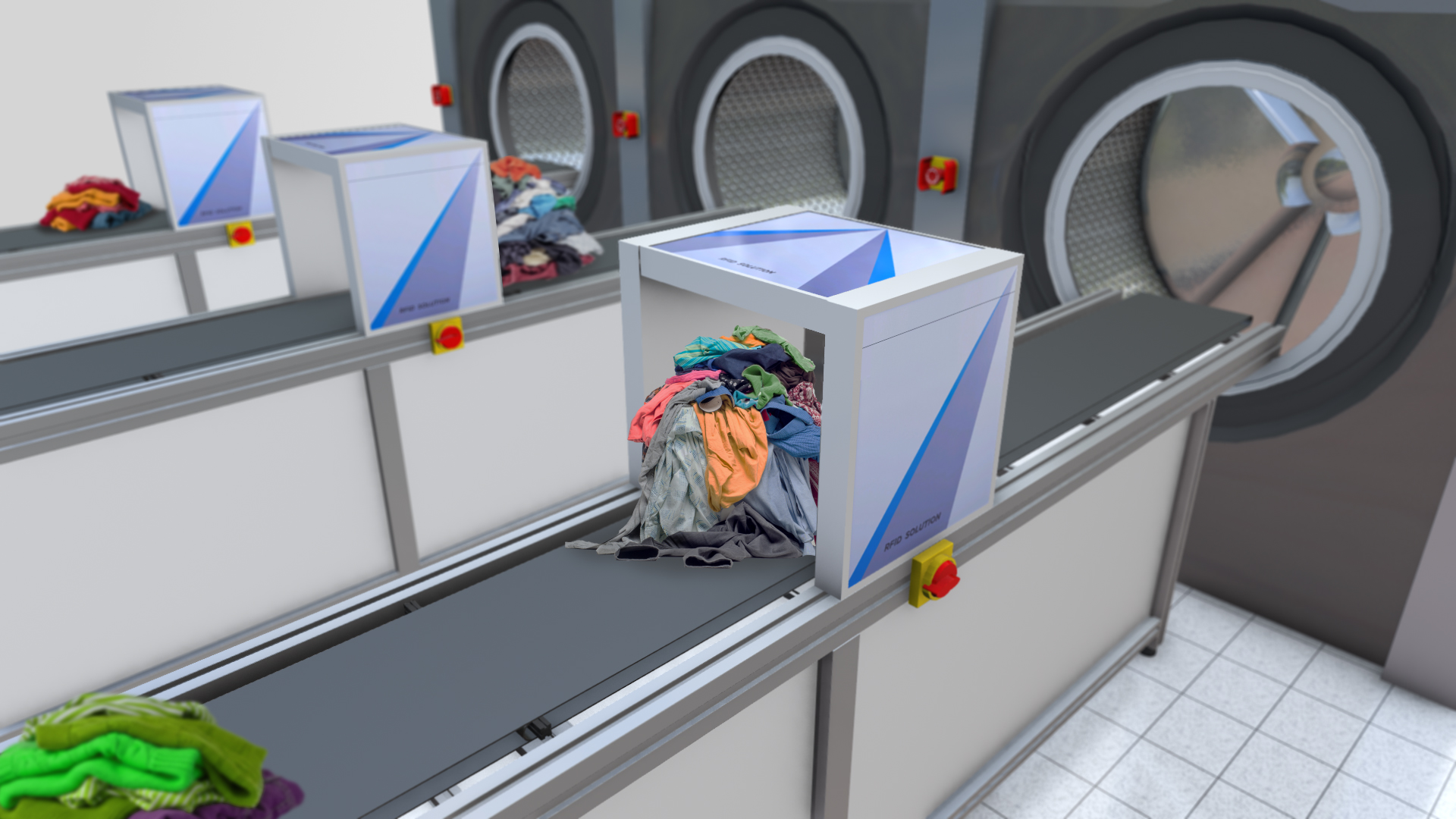

Laundries that handle hospital bedding and clothing need to check the quantity of items and sort them into categories for washing, then deliver the cleaned bedding and clothing to different hospitals. Solutions that can accelerate the quantity verification and category sorting processes will help improve management efficiency and facilitate accurate cost calculation.

Success Stories

Installing WNC RFID solutions at sorting stations, drying stations, and folding stations in laundries will enable tracking of items as they pass through stations, and the amount of time each item stays at a station can also be logged.

Benefits

The RFID system significantly improves management efficiency by tracking worker productivity and working hours, helping to set KPIs and optimize workforce allocation. Meanwhile, the accurate data provided by the system enables healthcare institutions to precisely calculate costs and turnover rates, thereby facilitating contract negotiations.