Production

PCBa Warehousing and Retrieval Management

In current SMT processes, personnel track the movement of PCBas by manually scanning barcodes. This scanning process is tedious and makes it difficult to track inventory quantities and locations in real time.

Success Stories

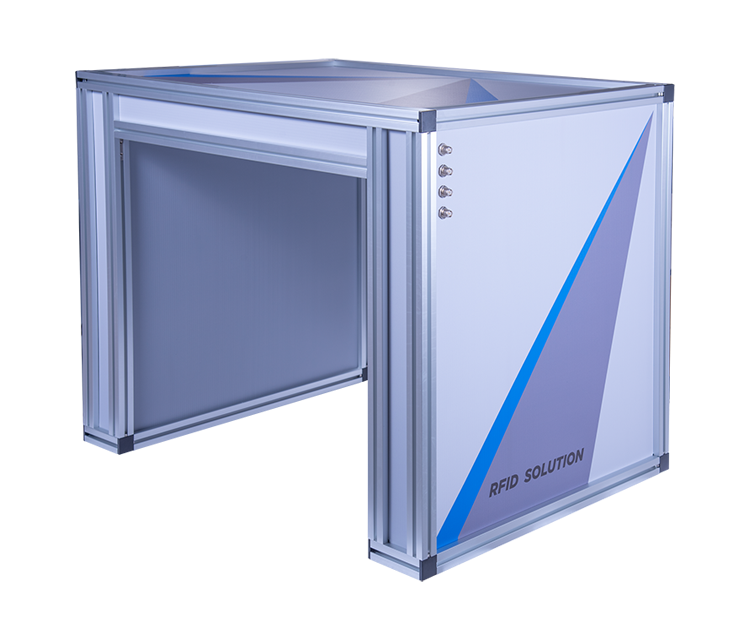

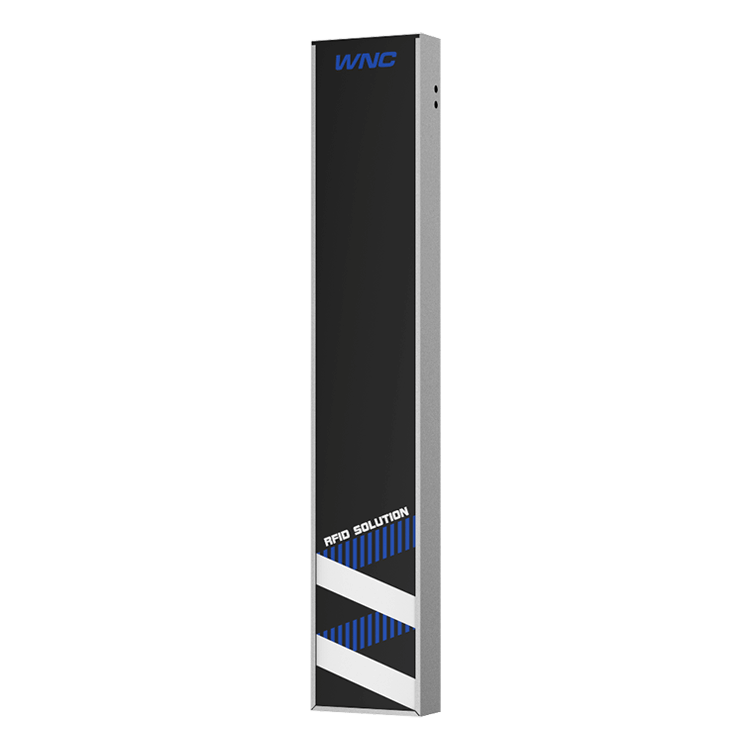

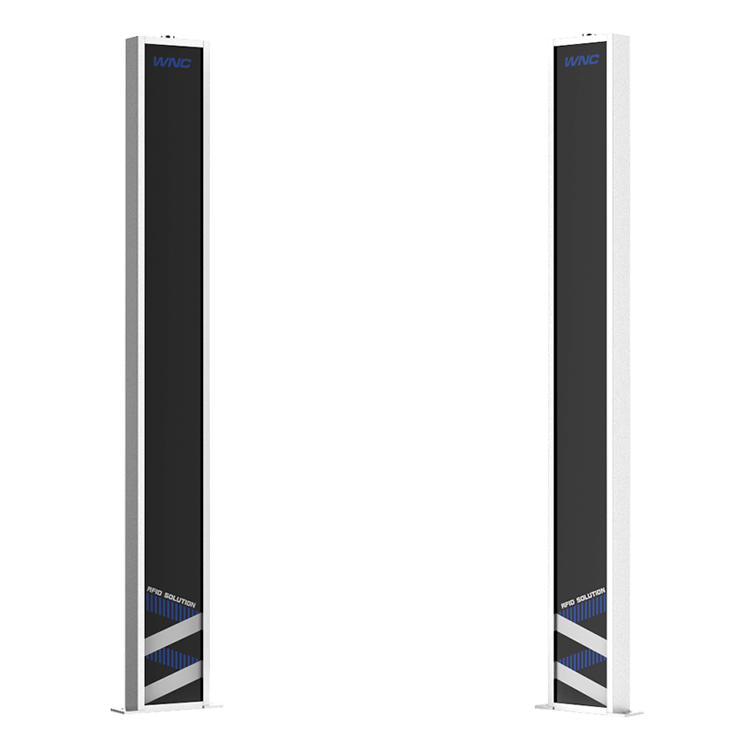

By installing the WNC RFID Tunnel or WAVE® Gate at required checkpoints and linking PCBas to anti-static trays, inventory and transaction records are automatically synchronized to the system as items pass through.

Benefits

RFID tags are paired during the depaneling process, enabling automated tracking throughout the entire workflow. This allows for real-time monitoring of inventory quantities and locations, enhancing inventory accuracy and reducing human error and operational mistakes.

SiP Process Control

In SiP processes, many key steps, such as baking, require strict control. If products are not properly baked or stored in an anti-moisture environment, serious quality issues may arise.

Success Stories

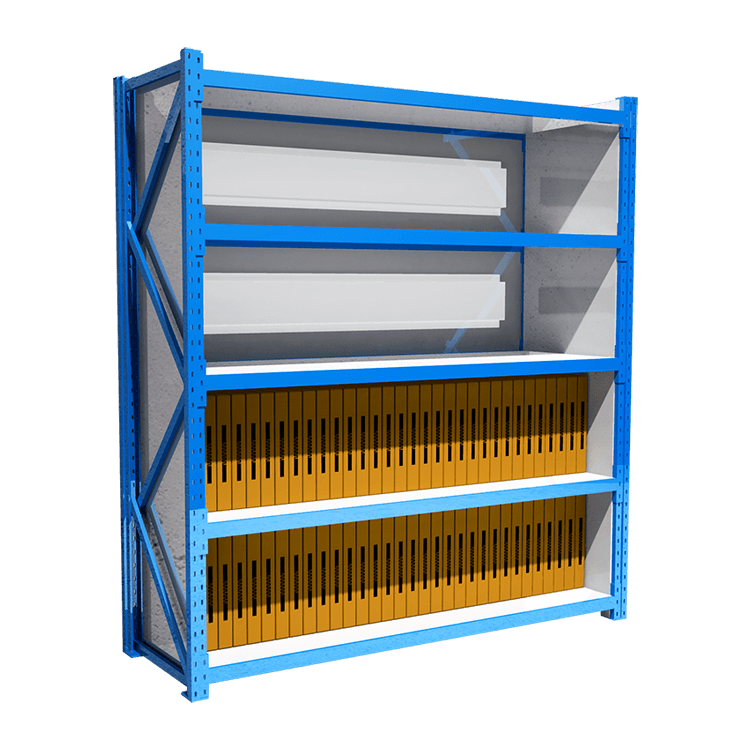

Integrating elements of our Electronic Shelf Solution with ovens or anti-moisture cabinets enables precise recording of when and how long products are placed in the designated devices, as well as accurate monitoring throughout the entire process.

Benefits

Real-time tracking of curing progress and the current production stage of each product helps improve management efficiency and reduce quality risks. The system also generates comprehensive reports to support customer communication and quality control.

Real-time Equipment Positioning and Monitoring System

Effective management and tracking of toolings are essential for production line management. Manual record-keeping increases the risk of information discrepancies, which can delay maintenance schedules and hinder tracking. This ultimately compromises production efficiency and quality.

Success Stories

WNC RFID portals can automatically detect and read information as toolings are moved into or out of production lines, enabling real-time tracking of their location and movement.

Benefits

Automated tooling movement tracking reduces manual inventory time and minimizes human error. It also enables real-time location monitoring, lowering the risk of production stoppage. Comprehensive movement and usage records are also generated to support subsequent data analysis and management optimization.

Preventive Maintenance (PM) Turnover Box Management

Scheduled preventive maintenance (PM) of machines plays a vital role in maintaining stable production line operations. PM tools are usually stored and managed in turnover boxes. If they are lost or cannot be located, it may delay the machine startup schedule, affect overall production capacity, and cause losses as well as management issues.

Success Stories

Storing the RFID turnover boxes on our Electronic Shelf Solution allows users to track the real-time location and access records of the PM turnover boxes through the system. When a box is taken out or returned, the system automatically updates its status, and anomaly alerts can be configured to enable real-time monitoring of PM tools.

Benefits

Regardless of box size, items are automatically read once placed on the shelf, enabling real-time tracking of inventory and location. The system issues immediate alerts when stock falls below the safety level and records retrieval times to reduce human error and operational risks.